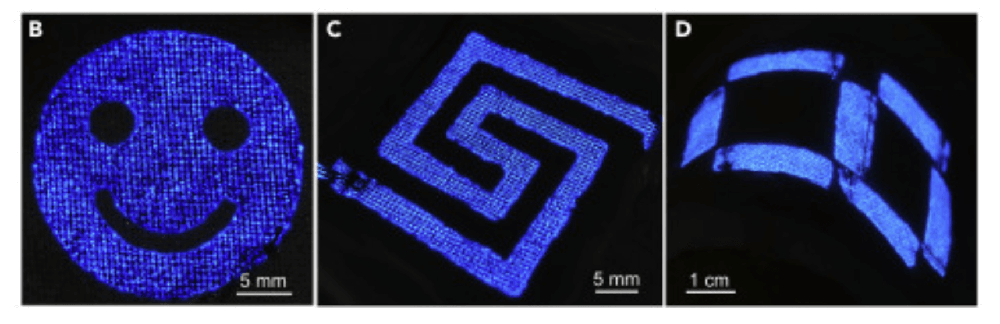

Photographs of light-emitting textiles displaying; (B) the "smiling face" emoji, (C) a rectangular spiral, and (D) the number 8.

Do you believe, in the near future, you may be able to have your own electronic clothes that can be chosen based on the sensors, indicators, and power sources embedded within them? Many researchers are taking it as a promising advancement in both the scientific and textile industry, I can’t wait to ask - are they really safe, durable, and comfortable?

For the first time in history, a team of researchers at the University of Windsor, Canada, used a new approach to create smart textiles with properties, they claimed, soft and wearable. The research along with future consequences was published in the journal Matter, on March 04, 2020.

The main challenge with the electronics that may be used in e-textiles is that the traditional electronics are not flexible enough and so it will hinder e-materials to seamlessly integrate its components. Also, there are flexible electronics, made by using thin-film technology, that can provide us with a different approach. This approach requires a flat and smooth surface which is extremely difficult work and this also limits other textile options. Moreover, weaving light-emitting fibers into woven fabrics can also do the job but this does not work in the case of knit fabrics which are more stretchable than woven fabrics.

The team led by researcher Tricia Breen Carmichael and Yunyun Wu, one of Carmichael’s Ph.D. students, at the University of Windsor, used a different approach and bypassed disadvantageous behavior of electronics.

The team used knit fabrics, a soft, wearable, material into a light-emitting device.

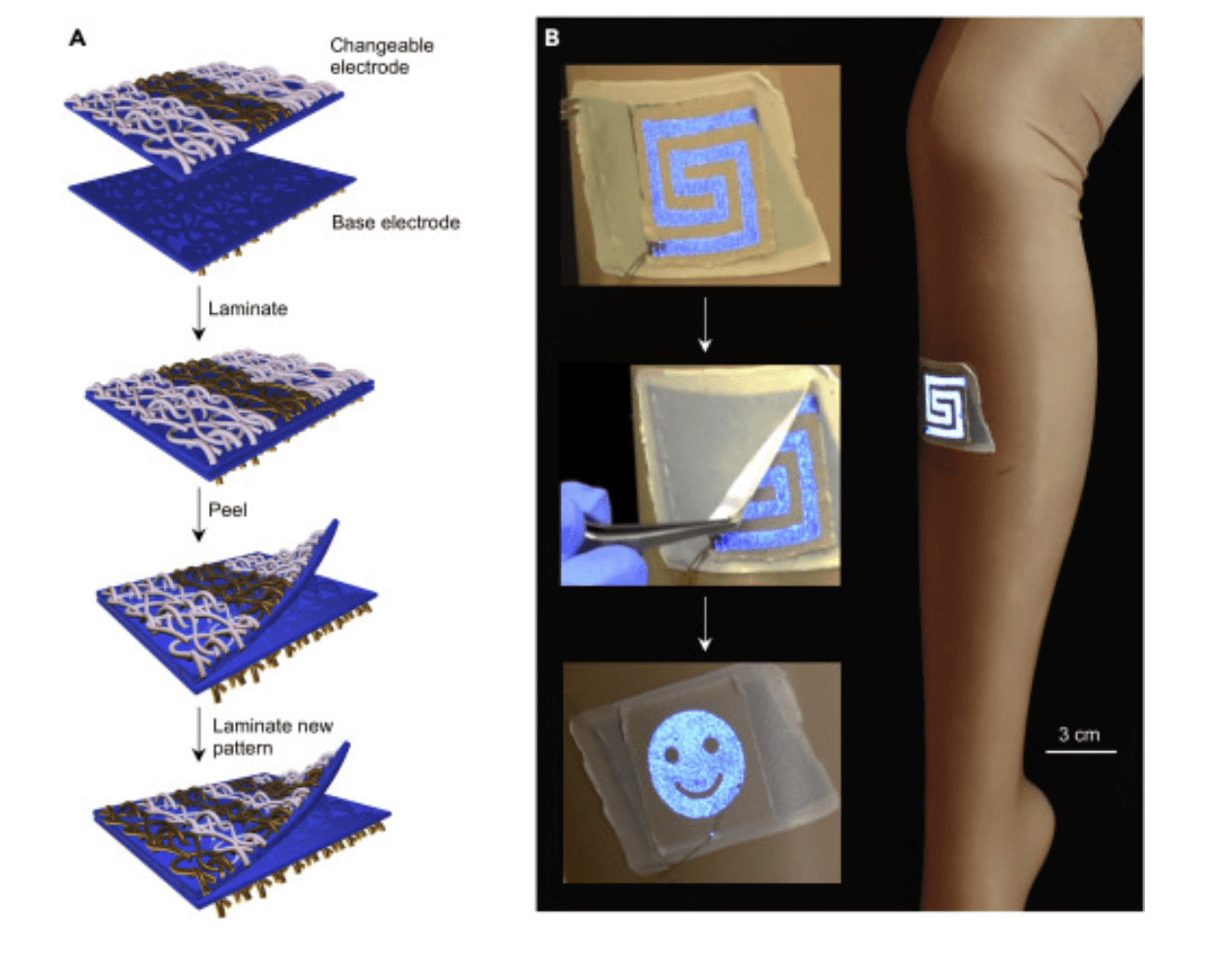

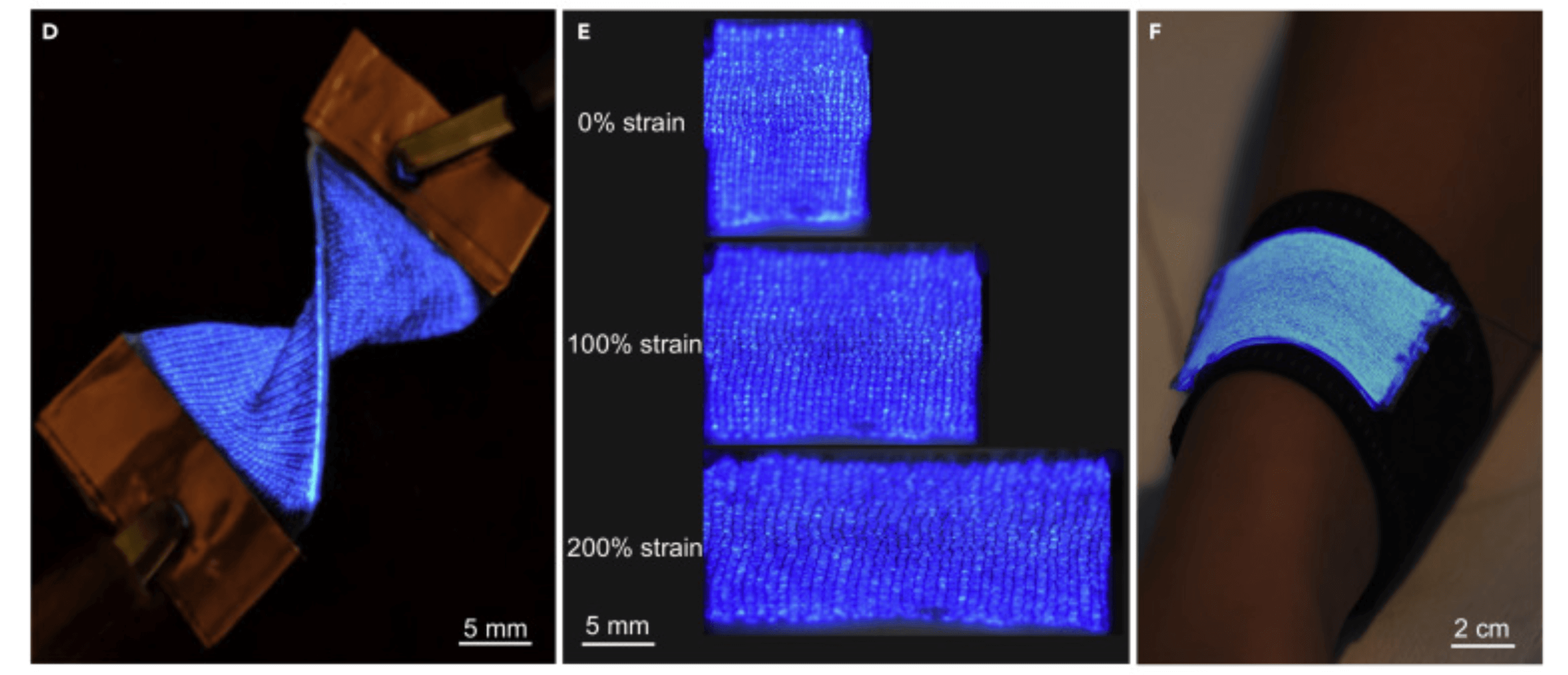

Instead of searching for new transparent and highly conductive films that have stretchable as well as wearable, the research team strategically used the open structure of an ultrasheer knitted textile as a framework for the fabrication of stretchable and semitransparent textile-based electrodes using solution-based metallization. The team used an ultrasheer knit fabric that could be stretched up to 200% and still return to its original shape. The fabric was 87% nylon and 13% spandex. Here, nylon provides strength and spandex added stretch and resiliency. The team coated the open framework structure of an ultrasheer knitted textile with a conformal gold film using solution-based metallization to form gold-coated ultrasheer electrodes that are highly conductive and retain conductivity to 200% strain. Finally to get the patterned lightings they used a low-cost stencil-printing method to fabricate patterned e-textile electrodes for patterned light-emitting displays. They used gold for coating because gold conducts electricity, is biocompatible, and chemically stable, so it’s safe for use in clothing.

The experiment was performed on the following four steps;

-

Electroless Nickel-Immersion Gold (ENIG) Metallization of Knitted Ultrasheer Fabric

-

Patterning of Knitted Ultrasheer Fabric

-

Electroluminescent Device Fabrication

-

Washing Durability

They used a solution-based metal deposition technique called Electroless Nickel-Immersion Gold (ENIG) metallization which is commonly employed in printed circuit board fabrication. This technique will produce an ultrasheer e-textile with high conductivity. Performing steps of chemical treatments and then scanning through Scanning electron microscopy (SEM) they found that that the ENIG process produces uniform gold coatings on both nylon and spandex fibers, with a coating thickness of ∼100 nm. They also found small wrinkles and cracks on the surface of gold-coated spandex fibers, but not on the surface of gold-coated nylon fibers.

On the result, they get that the coated fabric was still highly conductive even after it was repeatedly stretched, and the coating didn’t really impact the fabric’s softness and stretchability which suggested that it would work well in a wearable device. On testing the research team noticed that brightness varied with stretching but they are confident that even the dimmest glow was clearly visible.

The end result stated by the research team was that they were able to design a soft, lightweight, thin, wearable material that glowed even when stretched by as much as 200%.

Though I am enthusiastic about this new e-textile concept, I wonder whether or not this e-cloth will be a dustproof or not and if not then how do we wash it. From the initial testing, the research team is on their preliminary prediction that normal washing and drying may be possible, but this needs more and diverse testing before they are produced commercially.